Measurement ranges:

- pressure difference (ДД) — 1.6 kPa...16 MPa;

- excess pressure (ДИ) - 40 kPa...25 MPa;

- absolute pressure (ДА) — 10 kPA...16 MPa;

- hydrostatic pressure (ДГ) — 40 kPa.. 250 kPa.

PTs use load cell transducers (sensors) on the basis of silicon resistive strain gauges on a sapphire membrane “Silicon on sapphire” (КНС)

A PT has several structural designs: flanged design, choke design with a liquid, choke design without a liquid, special design (choke, flanged).

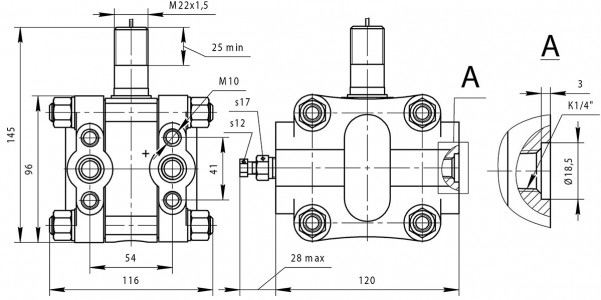

Flanged pressure transmitters have a measurement&transducing body frame in the assembly with flanges. The flanges provide for a process connection on the thread K1/4 or through an installed valve (globe valve) block. The body frame choke has a thread M22X1.5.

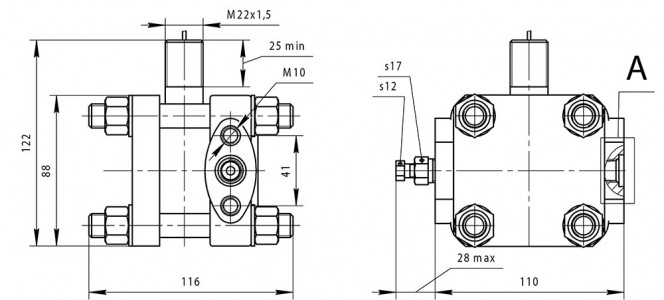

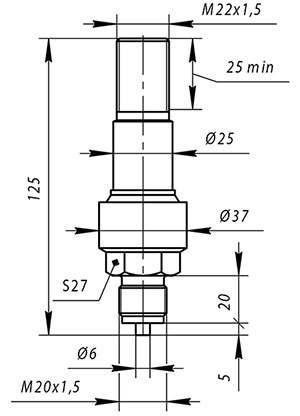

The ПД choke design with a liquid is made as a single measurement and transducing body frame. The body frame consists of an isolating membrane protecting a load cell transducer from aggressive media. The measured value is transmitted from the membrane to a sensitive element through the liquid filled into the internal cavity. The body frame provides for a process connection on the thread M20X1.5 or through an installed valve (globe valve) block. The body frame choke has a thread M22X1.5.

The ПД choke design without a liquid is made as a single measurement and transducing body frame. The measured value is directly transmitted to a sensitive element. The body frame provides for a process connection on the thread M20X1.5 or through an installed valve (globe valve) block. The body frame choke has a thread M22X1.5.

The special version of pressure transmitters can be made in compliance with any of the aforementioned version different in terms of process connection and the thread on the choke.

ПД electric supply is implemented by D.C. of not more than 1.5 mA.

The output signal range is from 90 mV to 400 mV depending on the model.

The ПД ingress protection rating corresponds to the group IP65 under GOST 14254.

Internal closed PT cavities are filled with the liquid PDMS-6 under GOST 13032-77. For the version with code "-K" - liquid ПЭФ-70/110 under TC 6-02-1072-76.