Used to stabilize a flow of the measured medium ahead of the flow orifice device by means of the elimination or decreasing of vortex flows induced by local resistances.

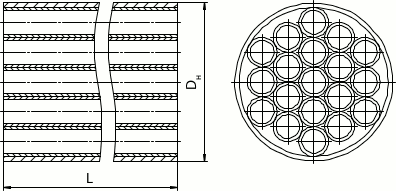

- It has a form of the cluster consisting of 19 tubes located in parallel to the pipeline axis and filling all its section.

- It is manufactured in three versions. Connecting dimensions of straightening vane flanges, version 1 and 3 correspond to GOST 33259-2015.

- To be mounted on a pipeline, a straightening vane can be supplied with a set of counter flanges.